In the 1970s, the Organization of Petroleum Exporting Countries (OPEC) closed its oil taps and sent oil prices soaring.

It was around this time that oil company, Exxon Mobil Corporation, decided that they needed to diversify from oil to create new revenue streams.

So, with this in mind, they hired a group of chemists and physicists to work on battery technology. Among the group was Dr M Stanley Whittingham.

As he told The Australian:

‘Exxon decided they wanted to be an energy company, not just an oil and chemical company. They thought oil would peak by about the year 2000. So we were allowed to work on anything in energy provided it wasn’t petroleum or chemical related.’

Whittingham and his team discovered that holding lithium ions between plates of titanium sulphide created electricity.

This breakthrough paved the way for the development of the lithium-ion batteries we use today in things like laptops, cell phones and electric vehicles (EVs).

Batteries are crucial for the energy transition

EVs…wind turbines…solar panels…for all, batteries play a key role. Batteries help store excess electricity to be used later when needed.

But lithium-ion batteries are a decades-old technology. What’s more, lithium batteries need massive amounts of critical minerals.

So, the battery industry is currently working frantically on two areas.

One is to improve existing lithium-ion batteries by trying to make them cheaper.

That’s one of the reasons why lithium iron phosphate (LFP) batteries have been gaining ground.

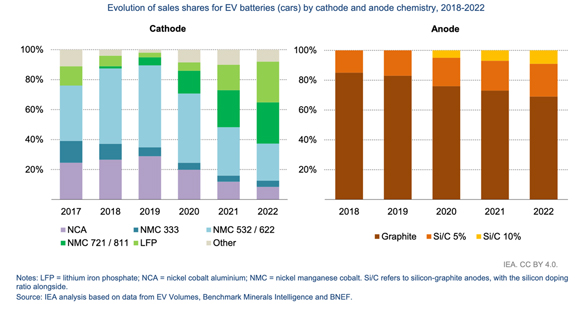

You see, lithium-ion batteries aren’t all the same. There’s more than one type, and they vary depending on the chemical composition of the cathode.

As you can see below, nickel manganese cobalt oxide (NMC for short) is the dominant lithium-ion EV battery today. But lithium iron phosphate batteries have been gaining share (in light green).

|

|

| Source: S&P |

LFP batteries have no nickel or cobalt. They are cheaper to produce and are more stable, although the downside is that they have less range.

The industry is also working on increasing driving range.

One interesting development in this area has come from Toyota. They’ve been busy developing a solid-state battery that would have a 1200-kilometre range and would recharge in 10 minutes…impressive.

Solid-state batteries have a solid electrolyte instead of a liquid one. They have higher energy density, are lighter, faster to charge, have a longer lifespan, and are safer and more stable when compared to traditional lithium-ion batteries.

But solid-state batteries are still pretty new. They are expensive and hard to manufacture at scale.

Still, solid-state batteries are something to keep an eye out for.

Working on the battery of the future

The other area the battery industry is working on is to create alternatives to lithium-ion batteries.

And there are plenty of companies experimenting with different types of batteries.

For instance, Contemporary Amperex Technology Co (CATL) — the largest lithium-ion battery manufacturer in the world — has started to produce a sodium-ion battery cell.

And EV manufacturer, BYD Co, is also planning to get some skin in this game. BYD has partnered with Huaihai Holding Group to build a sodium-ion battery plant in China.

As you may have guessed, the battery uses sodium, a material that’s way more abundant and cheaper than lithium.

So, this would make these batteries cheaper to produce than lithium-ion batteries. However, the disadvantage is that they have less energy density which currently may suit only smaller EVs.

More recently, we’ve also seen some breakthroughs in rechargeable zinc-air batteries. These use a zinc negative electrode and air as a positive electrode.

In a study published at EcoMat, engineers at Edith Cowan University used a mix of new materials to redesign zinc-air batteries.

As Dr Muhammad Rizwan Azhar, who led the project, said:

‘Rechargeable zinc-air batteries (ZABs) are becoming more appealing because of their low cost, environmental friendliness, high theoretical energy density, and inherent safety. With the emergence of next-generation long-range vehicles and electric aircraft in the market, there is an increasing need for safer, more cost-effective, and high-performance battery systems that can surpass the capabilities of lithium-ion batteries.’

In short, lithium-ion batteries may be the dominant battery right now. But when it comes to batteries, there could be a lot of disruption coming our way.

Best,

|

Selva Freigedo,

Editor, Fat Tail Commodities

Comments